Leader in the production of aesthetic and painted plastic components including high-end products

\\We work with some of the leading companies in the automotive and motorcycle industry, both nationally and worldwide. We also supply components for other sectors like furniture and furnishing accessories, small and large appliances, mobility solutions, agricultural machinery, sports equipment, technical and medical equipment, electronic equipment, lawnmowers and pressure washers, and industrial refrigeration.

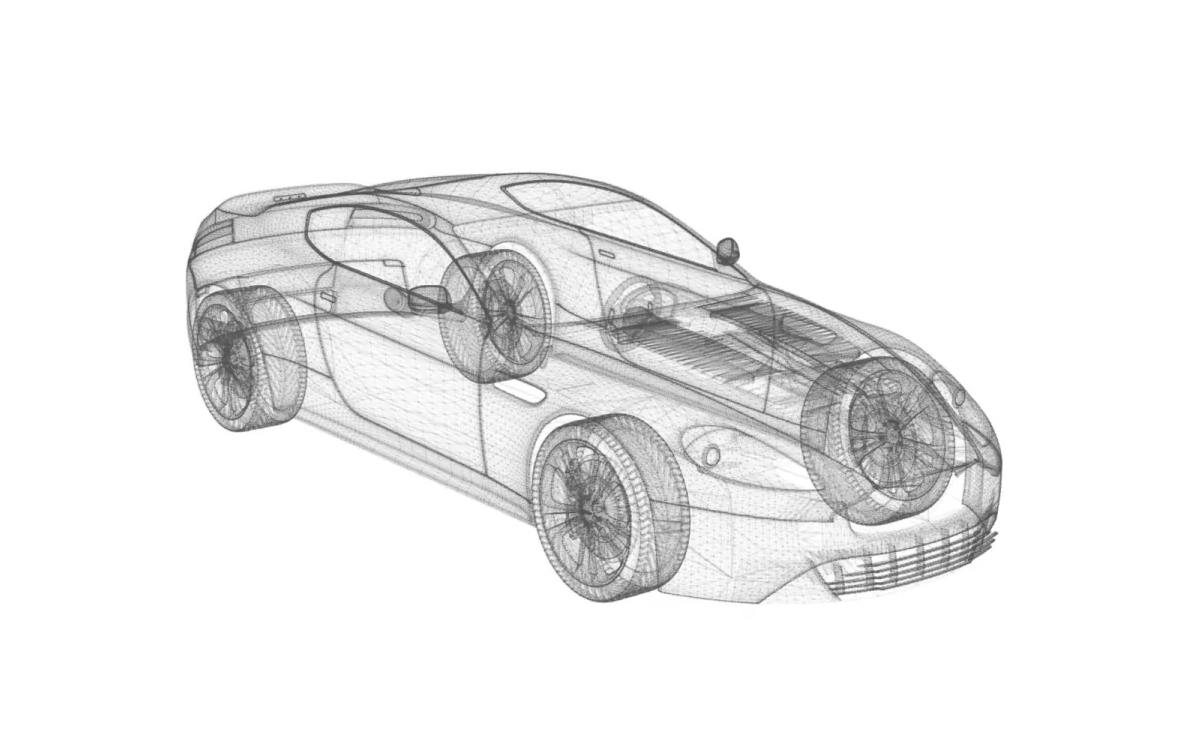

Design and Moulding

\\The design process and the injection moulding of plastic materials are completed with the painting of the resulting products, for which we use fully automated systems, suitable for both water-based and solvent-based paints.

Innovation

\\Our R&D department works with the support of a metrology room and a testing room equipped with technologically advanced tools. It is also supported by important certified external laboratories. Our R&D team performs strict quality controls on production and carries out research and design activities aimed to develop new materials, new industrial processes and new products that enable us to stand out on the market.

Sustainability

\\We have always focused on reducing the environmental impact of our production processes. The objective is to minimize energy consumption, the amount of polluting materials used, as well as the emissions of harmful substances. Part of our current production is carried out using recycled plastic and some of our production plants use photovoltaic systems.